Steam Air Retort

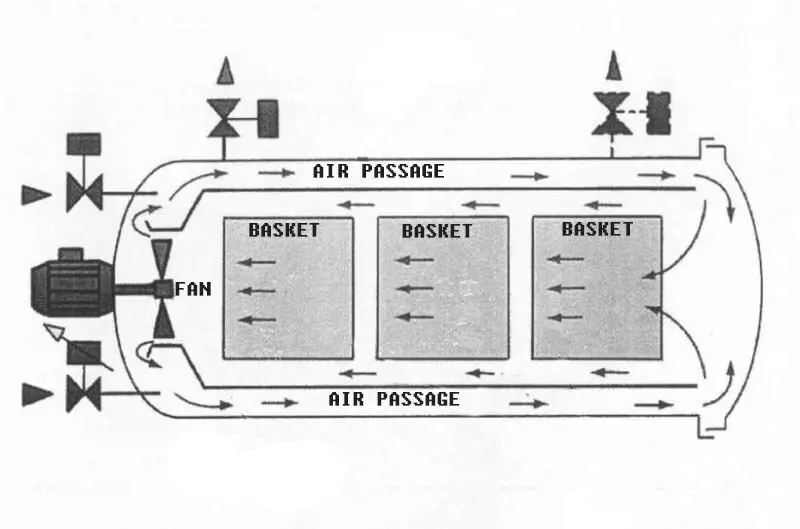

The steam air retort autoclave utilizes a fan system to drive the mixed steam and air for high temperature sterilization.

Hotline:

Email:

- Description

- Working principle

- Parameter

- Video

-

- Commodity name: Steam Air Retort

- Commodity ID: 1078690904467460096

The steam air retort autoclave utilizes a fan system to drive the mixed steam and air for high temperature sterilization.

Research and development purposes1. Compared with the traditional steam retort, the steam-air retort does not need to eliminate the cold air in the boiler during the sterilization process, and saves energy;2. Compared with the traditional steam retort, the steam-air retort can break the corresponding law of temperature and pressure under saturated steam, and realize the flexible control of the pressure under the steam sterilization process.Features1. No steam is required for cooling, the compressed air can be injected into the kettle. The unique turbine fan rotates to break the air cold group, forcing the steam and air mixture to circulate in the kettle. There is no absolute cold spot, and the heat distribution in the sterilization stage is controlled at ±0.5. °C;2. The ventilation turbine fan forces the steam-air mixture from one end to the other end of the kettle to be adsorbed to all products and perfectly covered to avoid the turbulence of the ventilation system, saving about 15% of steam;3. The driving backlight is designed according to the aerodynamic principle. The steam sucked from its starting point can control the flow direction and accelerate the heat transfer to the product center for heating and cooling;4. The pressure and temperature control is more free, can be back pressure cooling;5. Able applied to all kinds of packaging of snack foods, meat products, beverages and other high-temperature sterilization products;6. With negative pressure safety device, to avoid manual misuse, the formation of negative pressure, to ensure the safety of equipment;7. After the equipment is powered off, the program can automatically recover to the state before the power is cut off, reducing the loss;8. Equipped with triple safety interlock to prevent workers from mishandling and avoid accidents;9. Using double safety valve and dual pressure sensor control to prevent safety hazards.Application Products Customer Site

Customer Site Key words:

Key words:- Steam Air Retort

- canned meat retort line

- food retort

- luncheon meat retort technology

-

1. Put products into retort and close its door;2. Open the steam valve and air exhaust valve, and inject steam into retort; the fan does not start at this time;3. When most of the air in retort is removed, and the temperature reaches 100 degrees or above, close the air exhaust valve;4. Turn on the proportional steam valve to pass steam and start the fan for temperature come-up and sterilizing ;5. After the sterilizing ends, it enters the micro-cooling and full-cooling stage; the fan is still on in the micro-cooling stage;6. While the full cooling stage starts, the fan is turned off and products are cool to the process required temperature.

-

Model Dia. Drum L. Overall L. Overall W. Overall H. Volume Steam Consumption Power Tray Basket Design T. Design P. Testing P. (mm) (mm) (mm) (mm) (mm) (m³) (mm) (kw) (Set) (pcs) (℃) (MPa) (MPa) ZLPH/DL 900-2K 900 1800 3950 1550 2500 1.32 40 6.5 - 2 147 0.35 0.44 ZLPH/DL 1000-3K 1000 2400 3450 1850 2600 2.12 90 6.5 - 3 ZLPH/DL 1200-4K 1200 3600 4450 2150 2700 4.46 180 12.5 - 4 ZLPH/DL 1200-5K 1200 4000 4850 2150 2700 4.92 200 12.5 - 5 ZLPH/DL 1500-4K 1500 4200 5100 2500 3550 8.17 330 12.5 - 4 ZLPH/DL 1500-5K 1500 5250 6150 2500 3700 10.02 420 12.5 - 5 ZLPH/DL 1500-6K 1500 6300 7200 2550 3850 11.88 510 12.5 - 6 ZLPH/DL 1600-4K 1600 5500 6750 2600 3950 11.96 520 19.5 - 4 ZLPH/DL 1600-5K 1600 6600 7700 2700 4000 14.17 620 19.5 - 5 ZLPH/DL 1600-6K 1600 7100 8200 2700 4000 15.17 670 19.5 - 6

Prev

Next

Enquiry

Message Feedback

RELATED PRODUCTS